Utility-Grade Battery Management for Energy Storage

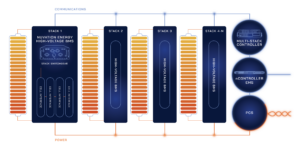

Nuvation Energy’s High-Voltage BMS provides cell- and stack-level control for battery stacks up to 1500 V DC. One Stack Switchgear unit manages each stack and connects it to the DC bus of the energy storage system. Cell Interface modules in each stack connect directly to battery cells to measure cell voltages and temperatures and provide cell balancing. This UL 1973 Recognized BMS ensures safe battery operation and significantly reduces the effort of pursuing UL 1973 and UL 9540 certification of the energy storage solution.

For parallel stack aggregation, an additional Nuvation Energy Multi-Stack Controller (MSC) can be included in the ESS. The MSC acts as a central control hub that combines all the Stack Switchgear units and enables the stacks to be managed as a unified battery system.

HIGH-VOLTAGE BMS FEATURES

- From kWh to MWh, the Nuvation Energy High-Voltage BMS manages up to 1500 V DC per battery stack and up to 16 stacks in parallel with the addition of a Multi Stack Controller.

- Connects and disconnects a battery stack to the DC bus of the ESS in response to requests from system controllers. Will also report the resulting capacity change to the PCS and other energy management systems.

- Measures cell- and stack-level voltage, temperature, and current. Calculates State of Charge (SOC), and Depth of Discharge (DOD) and provides this information to the PCS to enable precise charge/discharge control.

- Provides battery profile thresholds to the PCS, triggers warnings when approaching safety limits, can activate battery cooling fans.

- Will alter current limits to protect the battery from overcharge and over-discharge as well as to reduce battery temperature and to prevent over-voltage.

- Utilizes a pre-charge circuit when connecting the stack to the DC bus, to prevent current surges and voltage mismatches that could damage cells.

- Disconnects batteries from the power path if safety thresholds are exceeded during ESS operation.

- Includes short-circuit protection.

G5 High-Voltage BMS

Designed specifically for lithium-ion battery chemistries, Nuvation Energy’s new fifth-generation battery management system supports up to 1500 V DC battery stacks and modules that use cells in the 1.6 V – 4.3 V range. The G5 BMS offers cutting edge features such as continuous cell balancing and the ability to manage up to 36 battery cells with each series-connected Cell Interface module. Updates from the G4 BMS also include optimizations that significantly reduce the cost of wiring within the battery stack. The result is an average 25% reduction in the cost per kilowatt-hour footprint of the BMS (over the Nuvation Energy G4 BMS, based on a 1500 V DC energy storage system). The G5 BMS is UL 1973 Recognized for Functional Safety and is CE Compliant.

Watch the video of an interview with Nuvation Energy CEO Michael Worry, where he walks us through the G5 High-Voltage BMS and what makes it special.

G4 High-Voltage BMS

Nuvation Energy’s fourth-generation battery management system supports battery modules with cells in the 0-5 V range, and monobloc cells in the 5-20 V range. It is an excellent solution for a wide range of battery types, supporting all lithium chemistries along with zinc, lead acid, supercapacitors and many more chemistries with special characteristics. Deployed in hundreds of energy storage installations worldwide, this versatile and field-proven BMS is UL 1973 Recognized for Functional Safety.